PRODUCTS

-

Full Paper Valve Pocket

Material: It is made of imported or domestic stretchy kraft paper, the highest four layers of paper plus a PE film, bonded with food-grade water-borne adhesive.

Advantages: exquisite printing effect, high grade products, multi-layer dislocation perforation, multi-layer dislocation breaking, high sealing performance, especially suitable for ultra-fine powder material packaging.

-

PAPER-PLASTIC POCKET

Material: Sinopec high strength polypropylene (PP) material is used to weave cloth plus polyethylene (PE) material high temperature shower film, and imported extensible kraft paper is added. The inner paper can choose surface polyethylene (PE) material high temperature shower film, and the flat cloth is stitched in sticky.

Advantages: High tear strength of valve bottom, low breakage rate, light treatment can be used, strong and durable in line with multiple transport, double-layer staggered perforation, air permeability and material leakage, moisture-proof performance, especially suitable for food and ultra-fine powder material packaging.

-

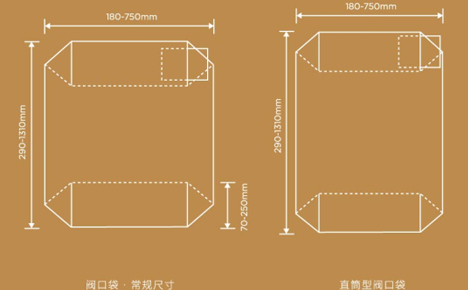

Square bottom open pocket

Material: Using imported or domestic extensible kraft paper plus polyethylene (PE) film and food-grade water-borne adhesives into the sticking drum.

Advantages: It is suitable for the traditional sewing sealing method. PE film can be added in the middle of the paper to pack the products which need moisture-proof.

苏公网安备

苏公网安备